Superior Durability and Material Strength for Demanding Applications

Oxford fabric makers who specialize in this stuff really focus on making their products last longer by carefully measuring denier levels and picking the right polymers for the job. Denier, or D as it's called, basically tells us how thick those fibers are. When we look at numbers, bigger means denser material. So 600D oxford has much thicker yarn compared to regular 300D fabric. Tests from Textile Research Journal back this up showing about 58% better wear resistance when using the ASTM D3389 method in 2023. Because of these properties, many industries rely on high denier oxford fabrics for things like safety equipment worn by workers and protective covers for expensive machinery parts that need extra protection against daily wear and tear.

Understanding Denier Ratings and Their Impact on Oxford Fabric Performance

Denier measures linear yarn mass (grams per 9,000 meters). Higher-denier fabrics offer:

- 22% greater tear strength in crosswise pull tests (ISO 13937-4)

- 35% improved puncture resistance against sharp objects

- 18% reduced fiber degradation after 500 UV exposure hours

These properties make high-denier oxford a preferred choice for applications requiring long-term structural integrity.

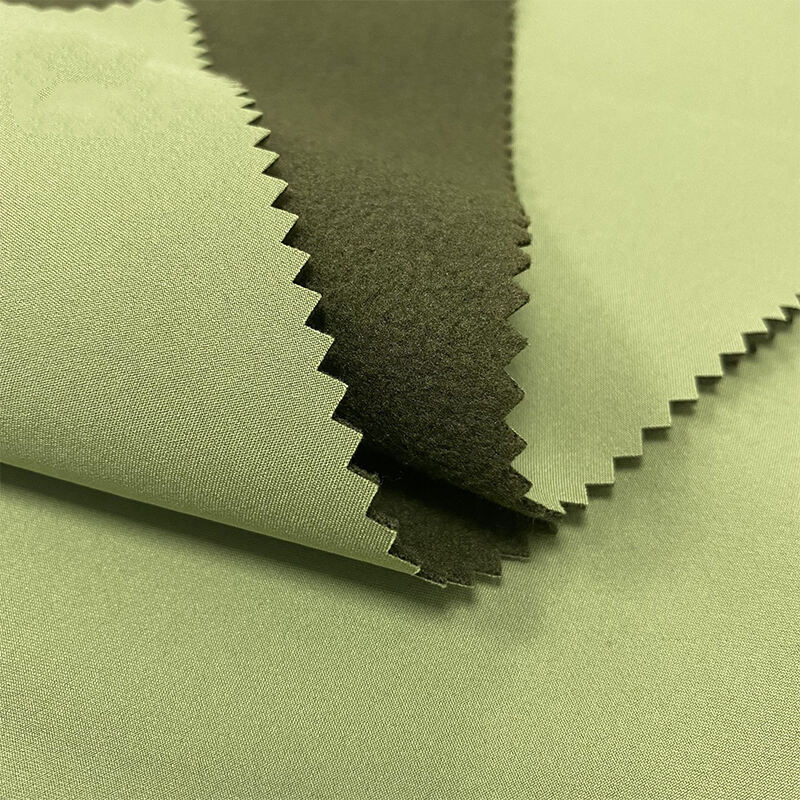

How 600D Oxford Fabric Ensures Abrasion Resistance and Long-Term Durability

The interlocking basket weave of 600D oxford forms a self-reinforcing structure that withstands over 15,000 Wyzenbeek rub cycles—exceeding automotive upholstery standards. Its resilience supports military-grade field gear designed for 5–7 years of service in extreme environments.

Comparative Strength of Polyester vs. Nylon Oxford in Industrial Use Cases

| Property | Polyester Oxford | Nylon Oxford |

|---|---|---|

| Tensile Strength | 220-260 MPa | 280-320 MPa |

| Moisture Absorption | 0.4% | 4.2% |

| UV Degradation | 8% loss @500hrs | 22% loss @500hrs |

Polyester is favored for outdoor use due to low moisture absorption and hydrolysis resistance, while nylon’s superior tensile strength suits impact-resistant barriers and dynamic load applications.

Key Characteristics of Oxford Fabric: Strength, Water Resistance, UV Resistance

Manufacturers enhance base materials with:

- Double-layer PU coatings (⇗5,000mm hydrostatic pressure)

- UV inhibitors blocking 98% of UVA/UVB radiation

- Anti-static treatments (⇗¹0^8Ω surface resistance)

- Heat-sealed seams maintaining water resistance at joints

These upgrades ensure performance across harsh environments without compromising flexibility.

Advanced Coatings and Finishes: PU, PVC, and TPU for Enhanced Performance

Waterproof Treatments (PU, PVC, TPU Coatings) in Oxford Fabric Production

Manufacturers typically apply three main coatings to enhance what oxford fabric can do. First there's polyurethane or PU which keeps water out at a reasonable price point. Then we have polyvinyl chloride known as PVC that provides serious protection against harsh conditions. And finally thermoplastic polyurethane TPU works best where flexibility matters most like when materials need to withstand constant movement. Fabrics treated with PU generally resist water pressure between 5,000 to around 10,000 mm according to tests. The really tough PVC versions can handle over 15,000 mm of pressure especially those used on boats and ships per Textile Standards Institute research from last year. What makes TPU stand out though is its ability to stretch up to 300 percent and still bounce back without any cracks forming. That property makes it great choice for outdoor equipment that gets bent and twisted repeatedly during normal use.

Advantages of TPU Over PVC in Eco-Friendly and Flexible Applications

TPU reduces carbon footprint by 38% during production compared to PVC (Global Textile Sustainability Report 2023). Free from chlorine-based toxins, TPU achieves 92% recyclability in closed-loop systems. It remains flexible in extreme cold (–40°C) and maintains 98% waterproof efficacy after 5,000 abrasion cycles, outperforming PVC in both sustainability and durability.

Role of Calendering and Coating in Enhancing Fabric Weather Resistance

The advanced calendering technique packs those yarns tightly together at around 120 threads per inch, which results in a really smooth surface measuring between 0.3 and 0.5 millimeters thick. This creates an excellent foundation where coatings stick evenly across the fabric. When we combine polyurethane with thermoplastic polyurethane layers, something interesting happens - the UV protection jumps up to UPF 50 plus rating. Fabrics treated this way still hold onto about 89% of their original strength even after being subjected to harsh lab tests simulating 3,000 hours of extreme weather according to ASTM G155 standards. What does all this mean? Gear made with these materials performs consistently well whether someone is hiking through heavy rains in the tropics, trekking across scorching deserts, or braving freezing temperatures in mountainous regions. And best of all, there's no peeling or separation issues despite whatever Mother Nature throws at it.

Customization and Sustainable Manufacturing Options

Design Versatility and Customization Options in Oxford Fabric Manufacturing

Leading mills leverage digital design systems to deliver tailored solutions, from custom UV-resistant weaves to specific tensile requirements. Modular production enables real-time adjustments, achieving <2mm tolerance across 50,000+ yard runs—critical for corporate merchandise requiring exact color and pattern consistency.

Eco-Friendly Variants and Sustainable Dyeing Processes

Closed-loop water systems reduce consumption by 63% versus traditional dyeing methods (Textile Sustainability Institute 2023). Over 78% of certified producers use OEKO-TEX® compliant pigments, eliminating heavy metals while maintaining colorfastness above 4/5 on the AATCC Gray Scale. This aligns with industrial sustainability benchmarks that emphasize ecological responsibility and product longevity.

Branding Integration Through Advanced Textile Engineering

Modern jacquard looms achieve 1200 DPI resolution for woven logos without weakening fabric integrity, supporting brand visibility in luggage and promotional items. Spectral analysis ensures ΔE ⇗¹1.5 color accuracy across batches, preserving corporate identity from prototype to scale. These capabilities transform oxford fabric into customized brand canvases while upholding performance standards.

Precision in Manufacturing: Weaving, Coating, and Quality Assurance

Step-by-Step Overview of the Oxford Fabric Manufacturing Process

Production begins with precision spinning of polyester or nylon into uniform yarns, followed by computerized weaving of the signature 2ÃÂ1 basket weave. Automated looms monitor tension 120 times per second, keeping thread density variance below 12%, ensuring optimal tear strength before coating application.

Ensuring Consistency in Fiber Thickness and Weave Tightness

Laser-guided systems measure fiber diameter every 0.5 meters, rejecting batches exceeding ±3μm tolerances. Real-time spectral analysis detects micro-weave flaws, enabling corrections within 0.8 seconds. These controls reduce warp/weft tension inconsistencies by 41% compared to conventional methods.

Role of Specialized Producers in Quality Control and Compliance

Top manufacturers follow a four-stage inspection protocol:

| Quality Parameter | Test Method | Industry Standard |

|---|---|---|

| Abrasion Resistance | Martindale Test | ISO 12947-2:2016 |

| Coating Adhesion | Peel Strength Measurement | ASTM D751 Section 19 |

| UV Resistance | Xenon Arc Exposure | AATCC TM16 Option 3 |

Third-party audits verify compliance with REACH and OEKO-TEX® standards in 98.7% of production batches (Global Textile Compliance Review 2023).

Balancing Cost-Efficiency With Premium Quality Standards

Predictive maintenance systems reduce equipment downtime by 37%, maintaining coating uniformity within 0.02mm tolerance. This efficiency delivers a 19% cost advantage while meeting the 50,000+ double-rub threshold required for military-grade 600D oxford fabric.

Proven Use Cases Across Backpacks, Travel Bags, and Corporate Merchandise

Applications of oxford fabric in bags: From outdoor gear to corporate merchandise

The combination of toughness and custom options makes Oxford fabric ideal for all sorts of bags. For outdoor gear like backpacks and duffels, people love how it stands up to UV damage and tearing. Corporate totes and laptop bags often have company logos built right into them, which stay looking good even after months of regular use. These branded bags basically become walking ads for businesses. Some studies suggest around 89 percent of folks who get these promotional items actually keep using them for more than a year. The waterproof 600D-PU coated variants tend to sell particularly well at trade shows and for staff packages, offering both practicality and that polished look companies want when handing out branded merchandise.

Why 600D oxford is preferred for travel bags and heavy-use backpacks

The 600D oxford fabric holds up really well in tough situations because of how tightly packed the fibers are and that distinctive basket weave look. Airport baggage handlers won't scratch it easily, nor will it wear down after going through dozens of laundry cycles according to recent tests by Textile Labs back in 2024. Most manufacturers actually prefer this weight class compared to lighter alternatives since it can withstand punctures about 18 percent better than thinner materials, which means whatever's inside stays protected while being transported around. What makes this fabric even more appealing is that despite all that durability, it still bends nicely for comfortable backpack straps and can handle weights as heavy as forty pounds without breaking down. That combination of toughness and flexibility explains why so many travel gear designers keep coming back to 600D oxford for their products.

FAQ Section:

What does "600D" mean in 600D Oxford fabric?

"600D" indicates the denier rating, which measures the thickness of the fabric fibers. A higher denier means thicker yarn and greater durability.

Why is Oxford fabric favored for outdoor gear?

Oxford fabric is favored for outdoor gear due to its superior abrasion resistance, UV protection, water resistance, and ability to withstand extreme environmental conditions.

What are the advantages of TPU over PVC?

TPU has a lower carbon footprint than PVC, is more flexible in extreme temperatures, and maintains higher waterproof efficacy after multiple abrasion cycles. It is also more sustainable with higher recyclability.

How do manufacturers ensure the quality of Oxford fabric?

Manufacturers use precision weaving techniques, real-time monitoring of fiber thickness, and strict inspection protocols to ensure fiber and coating consistency as well as UV and abrasion resistance.

Table of Contents

-

Superior Durability and Material Strength for Demanding Applications

- Understanding Denier Ratings and Their Impact on Oxford Fabric Performance

- How 600D Oxford Fabric Ensures Abrasion Resistance and Long-Term Durability

- Comparative Strength of Polyester vs. Nylon Oxford in Industrial Use Cases

- Key Characteristics of Oxford Fabric: Strength, Water Resistance, UV Resistance

- Advanced Coatings and Finishes: PU, PVC, and TPU for Enhanced Performance

- Customization and Sustainable Manufacturing Options

- Precision in Manufacturing: Weaving, Coating, and Quality Assurance

- Proven Use Cases Across Backpacks, Travel Bags, and Corporate Merchandise

- FAQ Section:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TR

TR

FA

FA

MS

MS

BN

BN

LA

LA

MY

MY