Trwałość: Fundament wysokiej jakości tkanin oxford

Zrozumienie odporności na ścieranie w wysokiej jakości tkaninach oxford

Tkaniny muszą charakteryzować się dobrą odpornością na ścieranie, gdy są stosowane w produktach takich jak torby, odzież terenową czy sprzęt przeznaczony do trudnych warunków. Wyróżniają się nimi wysokiej jakości tkaniny oksford, które znacznie dłużej wytrzymują zużycie mechaniczne. Te najwyższej jakości materiały czerpią swoją wytrzymałość z specjalnych mieszadek poliestrowych w zakresie 300D–600D oraz bardzo gęstych technik tkania. Zgodnie z wynikami badań opublikowanymi w zeszłym roku w czasopiśmie Textile Research Journal, najlepsze z nich wytrzymują ponad 50 000 cykli tarcia przed pojawieniem się uszkodzeń, co czyni je około cztery razy bardziej odpornymi niż zwykłe tkaniny nylonowe. I to nie tylko kwestia wydajności. Z raportu The Sustainability Directory wynika, że dzięki tym trwałym rozwiązaniom zmniejsza się ilość odpadów tkaninowych o około 15 kilogramów na jednostkę w całym cyklu życia produktu, co czyni je zarówno praktycznym, jak i ekologicznym wyborem zarówno dla producentów, jak i konsumentów.

Jak struktura splocenia koszykowego zwiększa wytrzymałość i trwałość

Konstrukcja tkaniny w stylu plecionki działa poprzez połączenie dwóch nitek osnowy z jedną nitką wątku, tworząc rodzaj siatki, która rozprowadza naprężenie po całej powierzchni tkaniny. Co czyni to interesującym, to fakt, że zwiększa odporność na rozerwanie o około 40 procent w porównaniu do zwykłych tkanin typu plain weave, zachowując jednocześnie wystarczającą elastyczność dla praktycznego użytku. Podczas testów te oksfordy o strukturze plecionki wytrzymują ciśnienie rzędu 72 funtów na cal kwadratowy. Dla porównania, odpowiada to możliwości podtrzymania około 470 funtów na każdy stopę kwadratową, zanim szwy zaczną pękać.

Wytrzymałość na rozciąganie i nośność materiałów premium Oxford

Wysokiej jakości tkanina oksford z włókien poliestrowych wytrzymuje naprężenia rozciągające w zakresie od około 220 do 320 MPa, co czyni ją doskonałym materiałem na takie rzeczy jak plecaki wojskowe czy wytrzymałe przemysłowe osłony. Weźmy na przykład poliester oksford 600D. Ten konkretny rodzaj potrafi udźwignąć nawet ponad 50 funtów (około 22,7 kg) podczas użytkowania w bagażu, przy jednoczesnym wydłużeniu się mniej niż o 1,5 procenta pod wpływem obciążenia. Powodem tak imponujących parametrów są specjalne polimerowe obróbki, które zwiększają gęstość włókien o 18–22 procent w porównaniu do wersji standardowych, według Raportu Instytutu Włókienniczego z 2024 roku. Naprawdę niezwykły materiał, jeśli pomyśleć, co mogą osiągnąć producenci dzięki tej klasie wytrzymałości.

Oksford wysokiej jakości vs. standardowy oksford: dane porównawcze żywotności

Testy przyspieszonego starzenia ujawniają istotne różnice:

| Wskaźnik wydajności | Oksford wysokiej jakości | Oksford standardowy |

|---|---|---|

| Średnia żywotność | 8–12 lat | 2,5–4 lata |

| Próg degradacji UV | 3 800 godzin | 1,200 Godzin |

| Cykle prania przed wystąpieniem wypłucia | 120+ | 35–50 |

Zgodnie z badaniem przeprowadzonym w 2024 roku przez Materials Engineering Review, wysokiej jakości tkaniny zachowują 92% swojej początkowej trwałości po pięciu latach użytkowania komercyjnego, w porównaniu do 58% dla gatunków ekonomicznych. Ta dłuższa żywotność uzasadnia o 25–40% wyższy koszt dzięki mniejszej liczbie wymian.

Odporność na wodę i właściwości środowiskowe

Skład materiału i jego rola we właściwościach odporności na wodę

Co sprawia, że wysokiej jakości tkanina Oxford skutecznie odpiera wodę? Otóż wszystko zależy od specjalnych mieszanek włókien i sposobu ich produkcji. Zgodnie z badaniami opublikowanymi rok temu przez Instytut Włókienniczy, gdy producenci mieszają około 70% poliestru z około 20% nylonu oraz niewielką ilością powłoki poliuretanowej, takie tkaniny potrafią odpierać niemal całą wodę podczas standardowych procedur testowych. Kluczem jest gęsty spój płatkowy połączony z różnymi polimerowymi powłokami, które skutecznie zamykają drobne przestrzenie między nitkami. Niektóre firmy idą jeszcze dalej, stosując obróbkę plazmową, która przyłącza cząsteczki odpornych na wodę bezpośrednio do włókien. Tworzy to coś wyjątkowego: materiał, który pozostaje suchy, a mimo to pozwala na przepływ powietrza, co czyni go wygodnym zarówno w sprzęcie turystycznym, jak i odzieży roboczej.

Mieszanki poliestrowe dla doskonałego odprowadzania wilgoci

Charakterystyka poliestru o właściwościach hydrofobowych pozwala wysokiej jakości tkaninom Oxford przeprowadzać wilgoć o 40% szybciej niż mieszanki bawełniane (Outdoor Industry Association, 2022). Zaawansowane wersje zawierają:

- Włókna elastyku hydrofilowe (8–12%) dla kierunkowego transportu wilgoci

- Bezfluorowęglowe powłoki DWR skuteczne przez ponad 50 praniek

- Wzajemnie zakleszczone nitki osnowy i wątku tworzące kanały kapilarne umożliwiające szybkie parowanie

Te cechy zmniejszają ryzyko pleśni o 62% w wilgotnych warunkach, co potwierdzono w testach laboratoryjnych (Outdoor Material Performance Review, 2023).

Studium przypadku: Wysokiej jakości tkanina Oxford w sprzęcie na ekstremalne warunki pogodowe

Gdy znana marka outdoorowa przebudowała swoje namioty wyprawowe na wysokiej jakości tkaninę Oxford 600D, wyniki wykazały znaczące ulepszenia:

| Metryczny | Standardowa tkanina | Premium Oxford | Poprawa |

|---|---|---|---|

| Ciśnienie słupa wody | 3 000 mm | 10 000 mm | 233% |

| Zachowanie wytrzymałości szwów | 68% po 5 latach | 92% po 5 latach | 35% |

| Wskaźnik degradacji UV | 15% roczna utrata | 4% roczna utrata | o 73% wolniejsze |

Tkanina zachowała 98% szczelności wodnej po 144 godzinach symulowanych warunków monsunowych (opady 120 mm/godz) i przy wietrze o prędkości 80 mph. Raporty z wypraw alpejskich potwierdziły brak przenikania wilgoci w temperaturze -40°C, co świadczy o niezawodnej wydajności w skrajnych warunkach temperaturowych.

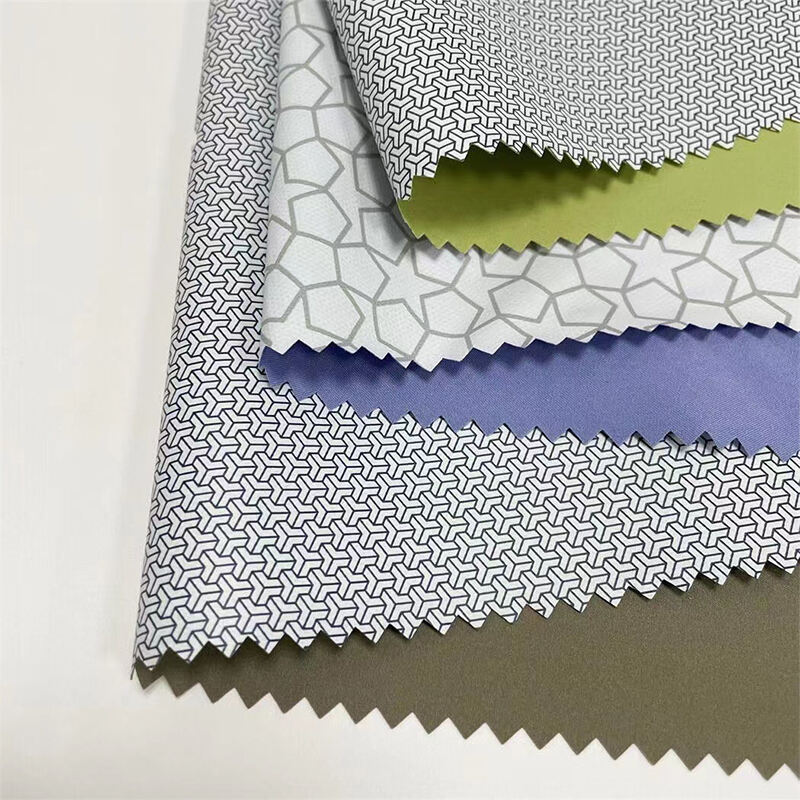

Skład materiału: Co odróżnia wysokiej jakości tkaniny Oxford

Bawełna, poliester i elastan: balans komfortu i wytrzymałości

Tkanina Oxford wykonana z wysokiej jakości materiałów łączy włókna naturalne i syntetyczne, zapewniając większy komfort i trwałość. Składnik bawełniany zapewnia przewiewność i miękkość w dotyku, podczas gdy poliester nadaje materiałowi odporność na wodę oraz dodatkową wytrzymałość. Zgodnie z badaniami opublikowanymi w 2024 roku przez inżynierów odzieżnych, mieszanki poliestrowe o gęstości 600D zachowują około 92% swojej pierwotnej wytrzymałości nawet po 5000 testach tarcia, co znacznie przewyższa zwykłe tkaniny bawełniane. Dodanie około 3 do 5 procent elastanu sprawia, że tkanina staje się znacznie bardziej elastyczna, zachowując jednocześnie charakterystyczny desenio plecionki typowy dla wysokiej jakości tkaniny Oxford. Większość producentów uważa, że ta kombinacja doskonale sprawdza się w produktach wymagających zarówno komfortu, jak i długotrwałej wydajności.

Kluczowe różnice w jakości włókien między standardowymi a wysokiej jakości tkaninami Oxford

Lepsza jakość tkaniny Oxford to włókna o grubości około 40% większej w porównaniu do standardowych, a ponadto są one tkane o około 20% gęściej. Te niewielkie zmiany jednak znacząco się przejawiają. Testy przemysłowe wykazały, że taka konstrukcja zmniejsza powstawanie irytujących zawiązów o około 65%, jednocześnie zwiększając nośność tkaniny o około 30%. Nie należy również zapominać o składniku poliestrowym. Wysokiej jakości odmiany są wyposażone w specjalne powłoki ochronne przed promieniowaniem UV, które zachowują większość swojej odporności na wodę nawet po trzech latach przebywania na zewnątrz. Standardowe mieszanki nie wytrzymują tak dobrze i zazwyczaj tracą skuteczność całkowicie już po 18 miesiącach, maksymalnie.

Trendy zrównoważone: Włókna recyklingowe w nowoczesnej produkcji tkaniny Oxford

Wiodący producenci integrują obecnie 30–50% wtórnego poliestru PET pochodzącego ze zużytych produktów w tkaniny oksfordzkie, nie rezygnując przy tym z trwałości. To podejście zamkniętego cyklu redukuje emisję dwutlenku węgla o 22% na jard w porównaniu z produkcją poliestru pierwotnego (Textile Exchange 2023). Dzięki zaawansowanym procesom recyklingu te zrównoważone włókna oferują retencję koloru na poziomie 98%, eliminując wcześniejsze ograniczenia eksploatacyjne związane z materiałami recyklingowymi.

Zastosowania w warunkach zewnętrznym, komercyjnym i przemysłowym

Właściwości tkaniny oksfordzkiej w walizkach, torbach i namiotach

Miłośnicy aktywności na świeżym powietrzu wiedzą, że wysokiej jakości tkanina oxford jest obecnie niemal wszędzie w sprzęcie, ponieważ potrafi być jednocześnie lekka i niezwykle wytrzymała. Weźmy te drogie, premium wersje z płaskim splocie, które według badań Instytutu Włókiennictwa z zeszłego roku mają wytrzymałość o 32 procent większą niż zwykłe tkaniny. To właśnie to decyduje o różnicy podczas pakowania sprzętu do plecaków czy rozbijania obozu na trudnym terenie, gdzie tkanina ociera się o wszystko. Dla producentów torb i walizek ważna jest klasa wytrzymałości 600D i więcej, ponieważ materiały te wytrzymują ciśnienie rzędu 50–70 kg, zanim włókna zaczną się rozchodzić. Mało dziwi, że podróżnicy polegają na tym materiale sezon po sezonie, mimo stosunkowo wysokiej ceny.

Zastosowania komercyjne w przemyśle i aplikacjach wojskowych

Tkaniny oksford o gramaturze od 900D do 1680D stały się powszechnie stosowanym materiałem do pokrywania maszyn przemysłowych, a także sprzętu wojskowego przenoszonego przez żołnierzy. Badania przeprowadzone w 2023 roku, obejmujące dwanaście różnych zakładów produkcyjnych, ujawniły ciekawe wyniki. Kierownicy zakładów donosili o oszczędnościach rzędu czternastu tysięcy dolarów rocznie na kosztach wymiany, gdy przełączyli się na te wytrzymalsze pokrycia oksford, które znacznie lepiej oprawiały się przeciwko uszkodzeniom chemicznym i działaniu promieni słonecznych w dłuższym okresie czasu. Obserwując sytuację w sektorze wojskowym, widzimy podobne tendencje. Obecnie większość sił zbrojnych wymaga, aby ich plecaki taktyczne były wykonane z specjalnie powlekanych wersji tkaniny oksford. Plecaki te muszą wytrzymać trudne warunki i noszenie dużych ciężarów, dlatego producenci testują je, aż osiągną wytrzymałość na rozciąganie przekraczającą 1200 funtów na stopę kwadratową, zanim zostaną zatwierdzone do użytku terenowego.

Wybór odpowiedniej wysokiej jakości tkaniny oksford dla konkretnych potrzeb funkcjonalnych

| Zastosowanie | Zalecana gęstość | Kluczowe rodzaje obróbki |

|---|---|---|

| Rekreacja na świeżym powietrzu | 420D–600D | PU odporny na wodę |

| Sprzęt przemysłowy | 900D–1200D | PVC ognioodporny |

| Wojskowy taktyczny | 1680D | Wzmocniony teflonem |

Dobierz gramaturę tkaniny do oczekiwanych obciążeń: 420D wytrzymuje do 25 kg, podczas gdy 1680D radzi sobie z ciężarami powyżej 80 kg w zastosowaniach wojskowych. W wilgotnych warunkach wybieraj tkaniny oxford z szwami pokrytymi silikonem, aby zapobiec przedostawaniu się wody, zachowując przy tym przepuszczalność powietrza w sprzęcie ochronnym.

Często zadawane pytania dotyczące wysokiej jakości tkanin oxford

Co sprawia, że wysokiej jakości tkanina Oxford jest tak trwała?

Trwałość wysokiej jakości tkaniny Oxford wynika ze specjalnych mieszadeł poliestrowych oraz gęstej konstrukcji splocenia typu koszyczkowego, co zapewnia znaczną odporność na ścieranie i dłuższą żywotność w porównaniu do standardowych tkanin nylonowych.

W jaki sposób struktura splocenia typu koszyczkowego wpływa na wytrzymałość tkaniny Oxford?

Struktura splocenia typu koszyczkowego rozprowadza naprężenia po całej powierzchni tkaniny, zwiększając odporność na rozerwanie o około 40% w porównaniu ze sploceniem płaskim, zachowując jednocześnie elastyczność niezbędną w użytkowaniu.

Jaką rolę odgrywa skład materiału w odporności na wodę tkaniny Oxford?

Wysokiej jakości tkanina Oxford wykorzystuje mieszanki włókien z powłokami odpornymi na wodę, które jednocześnie pozwalają na przepływ powietrza, zapewniając komfort i trwałość w sprzęcie turystycznym i odzieży roboczej.

Dlaczego w produkcji tkaniny Oxford stosuje się włókna recyklingowe?

Włókna recyklingowe pomagają zmniejszyć emisję dwutlenku węgla i zapewniają wysoką wydajność poprzez integrację folii PET pochodzącej z recyklingu odpadów komunalnych, co czyni tkaninę zrównoważoną bez kompromitowania trwałości.

W jakich branżach najczęściej wykorzystywane są tkaniny oksford?

Tkaniny oksford są stosowane w sprzęcie turystycznym, bagażu, osłonach maszyn przemysłowych oraz zastosowaniach wojskowych ze względu na ich wytrzymałość, trwałość i różne ochronne powłoki.

Spis treści

- Trwałość: Fundament wysokiej jakości tkanin oxford

- Odporność na wodę i właściwości środowiskowe

- Skład materiału: Co odróżnia wysokiej jakości tkaniny Oxford

- Zastosowania w warunkach zewnętrznym, komercyjnym i przemysłowym

-

Często zadawane pytania dotyczące wysokiej jakości tkanin oxford

- Co sprawia, że wysokiej jakości tkanina Oxford jest tak trwała?

- W jaki sposób struktura splocenia typu koszyczkowego wpływa na wytrzymałość tkaniny Oxford?

- Jaką rolę odgrywa skład materiału w odporności na wodę tkaniny Oxford?

- Dlaczego w produkcji tkaniny Oxford stosuje się włókna recyklingowe?

- W jakich branżach najczęściej wykorzystywane są tkaniny oksford?

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TR

TR

FA

FA

MS

MS

BN

BN

LA

LA

MY

MY