Well, recycling is a super neat thing that we can do to protect the planet. Let me tell you a bit about recycled TPE film today. Have you ever heard of it? If not, buckle your seatbelt because we’re all going to learn about it together. There are several advantages of recycled TPE film. A major benefit of this is the decrease in waste. Now, instead of just throwing it in the trash, we recycle old TPE film and create something new! This prevents our landfills from overflowing and is a benefit for the environment.

So, what about TPE film recycling? The process is honestly quite simple. The first step is to collect and clean the used TPE film. After that, we crush it and make it into small bits called pellets. The pellets can then be used to produce new TPE film. Hold the key to greener tomorrow Recycled TPE film By recycling TPE film, we help prevent waste being sent to landfills. That helps to protect our planet and ensures a clean and healthy home for future generations.

Recycling TPE film also means saving resources. By reusing old TPE film, we now use fewer new materials we would have had to extract from the earth. This contributes to the preservation of our natural resources.

It all begins when we take old TPE film to a recycling center. At TPE film enters the center, where the film is sorted and cleaned before being reduced to pellets. These pellets are then utilized in the production of new TPE film products.

Those new products are then delivered to manufacturers, who use them to make everything. Such products could range from packaging products to residential products. Old things can be transformed into new and useful things.

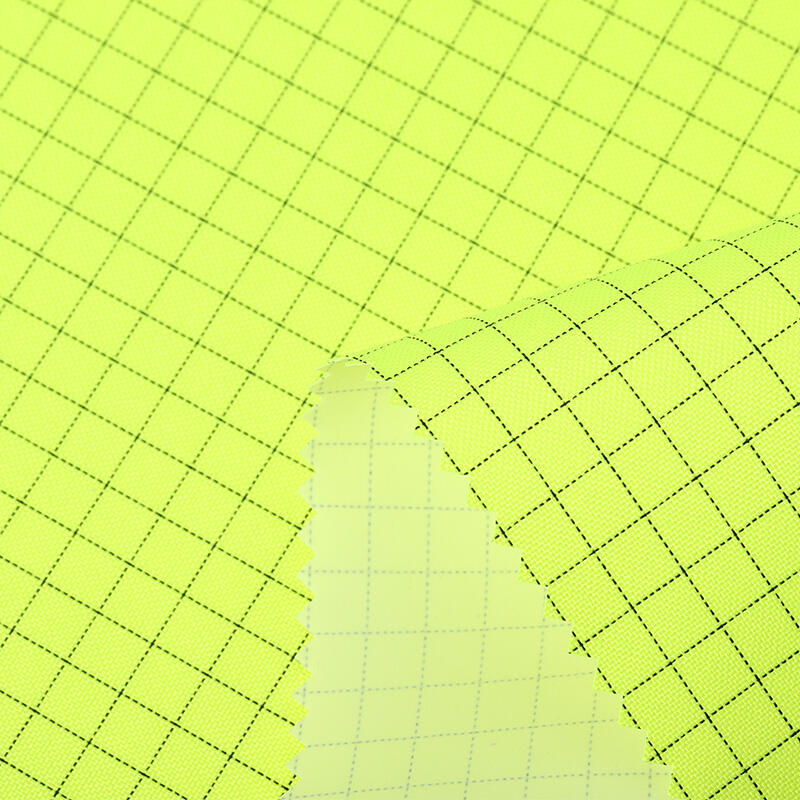

Fuhuang Textile operates a state-of-the-art production facility equipped with 28 sets of advanced PUR bonding machines, mainly laminate waterproof tpu pu ptfe tpee 2 layers or 3 layers softshell fabric, enabling a daily output capacity of 300,000 meters of high-quality fabric. This large-scale production capability ensures the company can meet the demands of bulk orders while maintaining consistent quality and on-time delivery. The efficiency and reliability of their production processes make Fuhuang Textile a trusted partner for clients seeking high-volume, high-performance textile solutions.

With 15 years of expertise in the textile industry, Fuhuang Textile has developed a deep understanding of functional fabrics, particularly in outdoor waterproof textiles, medical applications, and sportswear. This extensive experience allows the company to deliver products that meet the highest standards of quality, durability, and performance. Their seasoned team of professionals is adept at addressing complex customer requirements, ensuring that every project is executed with precision and expertise. This long-standing experience positions Fuhuang Textile as a leader in the global textile market.

Fuhuang Textile has consistently demonstrated its commitment to innovation, particularly with the development of its 3D down jacket fabric technology in 2018. This breakthrough technique transforms traditional fabrics, giving them a dynamic, three-dimensional appearance that enhances both functionality and aesthetics. With over 3,000 unique patterns created and 24 specialized machines, the company offers extensive customization options, including ODM logo services, to meet the specific needs of global brands and designers. This focus on innovation ensures Fuhuang Textile remains at the forefront of the functional textile industry.

Fuhuang Textile has built a strong international presence, exporting its products to 45 countries and establishing lasting relationships with clients worldwide. This global reach is a testament to the company’s ability to adapt to diverse market needs and deliver tailored solutions. By fostering close collaborations with customers and offering personalized services, Fuhuang Textile has earned a reputation for reliability and customer satisfaction. Their commitment to building successful business partnerships continues to drive their growth and competitiveness in the global textile industry.